Are you here:Home >

【 wei bearing cold bending steel cold bending steel in the design of the requirements?

What are the requirements for the design of cold-formed steel sections?Wuxi Weicheng Cold Bending Steel Co.,Ltd.Xiaobian with you to understand

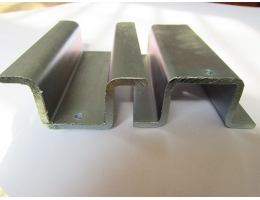

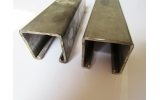

In the process of operation,the cold formed section steel is mainly made of carbon steel,high quality carbon structural steel,low alloy structural steel and stainless steel hot rolled,cold rolled strip steel as raw materials,and is formed into various cross-section copper by rolling bending.

Continuous cold-forming steel forming unit mainly includes uncoiling,straightening,shear butt-welding,storage,forming(welding,shaping),cutting off the size,inspection and collection and some special procedures,its equipment and high frequency welded pipe unit is basically similar,but the form of cold-forming machine is more diverse,According to the product specifications,it can be divided into three types:general cold-formed steel forming unit,open cold-formed steel forming unit and wide wave steel plate forming unit.These three types of units have different structure and product focus range.The general cold forming steel unit can produce not only cold forming copper products with simple section but also welded closed profile,such as round tube,square tube and other special shaped pipe.

Cold-formed steel sections are products that use a series of continuous stands to roll stainless steel into complex shapes.They are suitable for the production of sheets and special-shaped wires.The sequence of rolls is designed to allow the product to be gradually deformed.The mill is controlled by automation and the roll shape of each stand can be progressively and continuously rolled until the desired product shape is obtained.If the shape of the parts is complex,36 racks can be used,but the shape of the parts is simple,three or four racks can be.Rolls are often made of cold-work die steel,and the hardness is generally above HRC62.At the same time,in order to ensure the surface finish of the workpiece after rolling,the surface finish of the roll is also required to be very high.It is more economical to use roll forming technology to produce large quantities of long parts.For conventional sheet mills,the width range of strip steel that can be machined is 2.5mm~1500mm and the thickness is 0.25mm~3.5mm.For a conventional wire mill,the width range of wire that can be machined is 1 mm~30mm,and the thickness is 0.5 mm~10mm.The roll forming method is used to manufacture parts in a wide variety of shapes,ranging from simple planes to complex,closed sections.

Keyword:Cold-formed steel sections

Article source:http://www.wxwclw.cn

- Weicheng takes you to understand the application of cold formed steel in construction industry

Wuxi Weicheng Coldformed Steel Co.,Ltd.Xiaobian with you to see the application of cold formed steel in the construction industry!In modern architectu...

- Wei bearing to tell you the difference between the cold bending steel and ordinary steel structure

Cold-formed steel is a general term for a class of steel, including C section, Z section, square and rectangular tube, color steel tile and a series o...

- The development trend of cold formed section steel

Cold-formed steel also has great market potential in the machinery manufacturing industry,especially in the automobile manufacturing industry,such as ...

- Wei bearing cold bending steel tell you cold bending steel equipment operation procedures

Wutin city weicheng cold forming steel tells you the operation rules of cold forming steel equipment1.Strictly abide by the operation rules of cold-fo...

- Weicheng Cold Forming Steel Company introduces the production process of Cold Forming Steel

Different production and forming process of cold formed section steelThere are many kinds of cold-formed steel,from the shape of the section,there are...

- What is galvanized C-section steel? Wei Cheng tells you

What is galvanized C-section steel?Wuxi Weicheng Coldformed Steel Co.,Ltd.Xiaobian with you to see it!Galvanized steel plate refers to the use of high...